Introduction

Culture is the heartbeat of any successful digital transformation. It acts as the catalyst that unites technology and people to drive innovation and deliver real impact. Even the most well-funded programs can fall short if they neglect the cultural foundation needed to sustain momentum and adoption. Without embedding a digital-first mindset, transformation efforts often struggle to create long-term value.

In manufacturing, cultural transformation is especially challenging. Legacy systems, hierarchical decision-making, and risk-averse attitudes can slow the pace of change. Digital tools alone won’t shift the dial — it’s the people using them who drive progress. This requires a fundamental mindset shift: moving from “this is how we’ve always done it” to “how can we do it better with digital?” Changing how teams think, collaborate, and respond to new technologies is critical.

A digital-first culture puts innovation and adaptability at the core of operations. It promotes data-driven decision-making, continuous learning, and customer-centric thinking. When employees are empowered to see their roles through a digital lens, they’re more likely to champion new tools, challenge outdated norms, and drive smarter, faster outcomes across the business.

Digital transformation in manufacturing doesn’t end with a tool rollout or a budget approval. The long-term value comes from embedding digital into the DNA of the organization — making it part of how people think, act, and grow.

Exploring the key pillars of Digital-First Culture

Leadership & Vision: Setting the Tone for a Digital-First Culture

In any digital transformation, leadership sets the tone. Executives must not only endorse the digital agenda but actively model digital behaviours—embracing data-driven decisions, using collaborative digital tools, and prioritizing transparency and agility. A clear digital vision in manufacturing might look like committing to smart factories, predictive maintenance, real-time performance dashboards, and connected supply chains. But more importantly, it’s about translating that vision into action by aligning goals, empowering teams, and making digital performance a boardroom priority.

Culture flows from the top. If leaders don’t demonstrate digital behaviours, others won’t eitherExample

Bosch has successfully embedded digital thinking into its leadership DNA. Through its “Industry 4.0” program, executives championed the adoption of IoT and AI across plants globally. Their leadership was hands-on—they didn’t just fund initiatives but also participated in digital upskilling and promoted cross-functional agile teams. Similarly, Stanley Black & Decker launched a “Lighthouse Factory” in Mexico, with leadership driving lean-digital integration and workforce reskilling. These efforts not only improved productivity but created a strong cultural signal: digital transformation starts at the top, and everyone has a role in making it real.

Change Management Strategies: Turning Resistance into Readiness

Successful digital transformation hinges on how well change is managed—not just processes, but people. Resistance often stems from uncertainty, fear of redundancy, or lack of clarity. Effective methods to reduce resistance include early involvement of employees in decision-making, transparent communication, and quick wins that demonstrate the benefits of digital initiatives. More importantly, cultivating change champions—influential individuals within each plant or function—can accelerate adoption. These champions help contextualize digital change, dispel myths, and motivate peers to embrace new ways of working.

Change management is the glue that holds a digital-first culture together during transformation.Example

Unilever employed a change network during its supply chain digitization, embedding change agents at every site. These champions translated the vision into local terms, ran peer-led training, and maintained a feedback loop with corporate teams. As a result, adoption rates improved, and resistance decreased measurably.

Digital Literacy & Upskilling: Building the Workforce of the Future

Identifying and addressing digital skill gaps is critical. In manufacturing, gaps often lie in data analytics, IoT systems, digital maintenance tools, and automation platforms. Building a workforce ready for transformation requires structured learning frameworks that combine technical upskilling with change mindset coaching.

A culture can’t shift if people don’t feel equippedExample

Siemens developed its own digital academy with tiered learning paths based on employee roles. This enabled technicians, operators, and managers alike to adopt tools like digital twins and machine learning platforms confidently. Their “Learn and Apply” framework embedded training into daily operations, boosting both retention and performance.

Incentives and KPIs: Aligning Metrics with Mindsets

Measuring digital adoption requires more than tracking tool usage or logins. Meaningful KPIs include automation success rates, collaborative decision-making instances, innovation contributions, and speed of implementation. Incentives aligned to these KPIs can drive engagement and reinforce the desired digital behaviours.

What gets measured gets managedExample

Schneider Electric ties digital KPIs to both team and individual performance reviews, incentivizing process improvements and cross-department innovation. Recognition programs—both monetary and cultural—celebrate successful digital experiments, regardless of final outcomes, to foster an innovation-friendly climate.

Collaboration and Agility: Creating a Culture of Co-Creation

Cross-functional collaboration is essential for breaking silos that traditionally exist in manufacturing. Bringing IT, operations, maintenance, and engineering together in agile squads ensures holistic problem-solving. But beyond structure, psychological safety—the confidence to speak up without fear—is the secret sauce for innovation.

Fear of failure blocks innovationExample

Toyota applies its agile-inspired “Obeya” rooms across plants, encouraging real-time collaboration across departments. Teams use digital dashboards, run iterative improvement cycles, and openly discuss failures as learning opportunities—fostering agility and trust at scale.

Communication and Storytelling: Shaping the Narrative of Change

Transformation needs a compelling story—one that connects the vision to personal purpose. Strong internal communication strategies involve leaders frequently sharing updates, showcasing team success stories, and making the change journey relatable at every level.

Culture thrives on stories, not just statsExample

ABB launched an internal storytelling campaign alongside their digital factory rollout. They featured frontline workers in videos explaining how digital tools improved their daily work. This bottom-up storytelling built credibility and fostered a shared sense of ownership in the transformation journey.

Reference Table: Real-World Case Studies & Links

| Area | Company Example | Initiative/Reference |

| Leadership & Vision | Bosch | Industry 4.0 leadership model |

| Change Management | Unilever | Digital change champions network |

| Digital Upskilling | Siemens | Digital Academy |

| KPIs & Incentives | Schneider Electric | Innovation KPIs and employee engagement 🔗 |

| Collaboration & Agility | Toyota | Obeya room concept |

| Communication & Storytelling | ABB | Internal transformation storytelling |

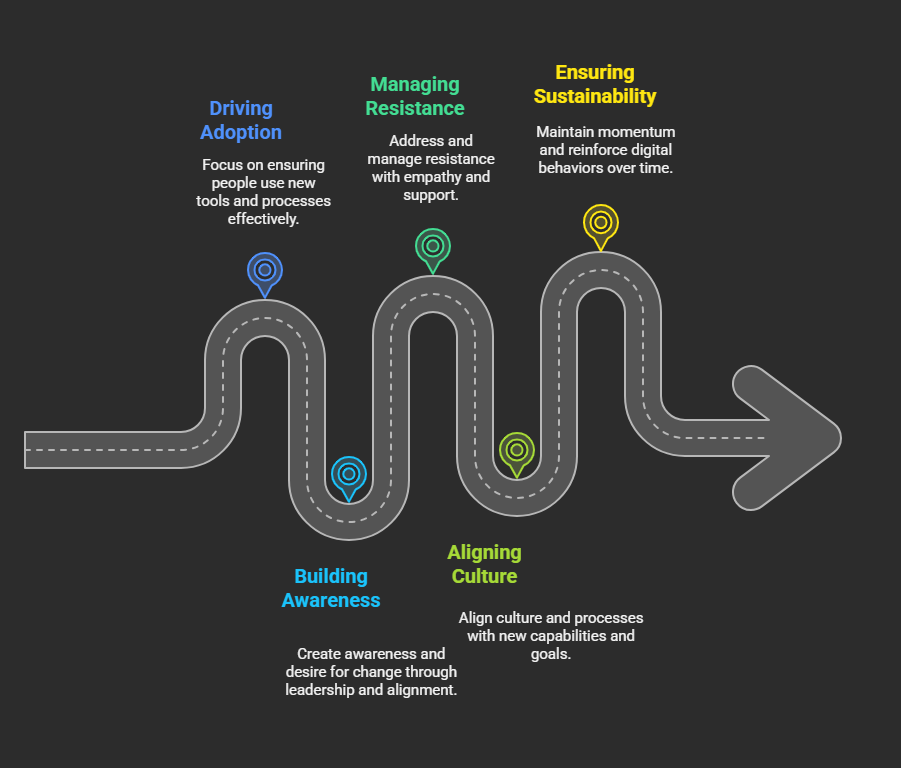

Driving Change through the business

Change management is a cornerstone of any successful digital transformation. It acts as the bridge between cutting-edge technology and the people expected to adopt it. Think of it as the lubricant in the engine of transformation — without it, even the best tools and strategies grind to a halt. Effective change management ensures employees aren’t just instructed to embrace a digital-first mindset; they’re enabled, supported, and empowered to live it every day.

To drive meaningful change, organizations should follow a structured approach:

Driving Adoption, Not Just Deployment

Even the best tech, tools, and training will fail if people don’t adopt them. Change management ensures employees understand:

- Why the change is happening.

- How it affects them personally

- What support they’ll get along the way?

Building Awareness, Desire, and Reinforcement

Change frameworks like ADKAR (Awareness, Desire, Knowledge, Ability, Reinforcement) are perfect for shaping a digital-first culture. You can embed these into each stage:

| ADKAR Stage | Cultural Action |

| Awareness | Leadership messaging, internal campaigns |

| Desire | Aligning digital with individual and team goals |

| Knowledge | Targeted training, digital academies |

| Ability | On-the-job support, champions, coaching |

| Reinforcement | Recognition, success stories, feedback loops |

Managing Resistance with Empathy

Change management helps spot and address the natural resistance that comes with shifting mindsets. In manufacturing, this might come from:

- Fear of job loss due to automation

- Discomfort with unfamiliar tools.

- Distrust in “corporate” initiatives

Aligning Culture with Capability

Change management isn’t just about people; it’s about aligning culture, leadership, processes, and technology:

- Updating job roles and org structures

- Embedding digital KPIs into performance systems

- Coaching leaders to model the new behaviours.

Ensuring Sustainability

Culture change isn’t a launch event — it’s a long game. Change management keeps the momentum going after go-live, through:

- Ongoing communication

- Measurement & feedback

- Continuous reinforcement of digital behaviours

Conclusion

A successful digital transformation isn’t just about investing in the latest technologies — it’s about reshaping the mindset of the entire organization. At the heart of this shift lies a digital-first culture, one where innovation, agility, and data-driven decision-making are embedded into daily operations. But culture doesn’t evolve on its own. It requires intentional change management and strong leadership to guide the way.

Leadership plays a pivotal role in modelling digital behaviours, setting a clear vision, and creating psychological safety for teams to experiment, fail fast, and learn. Communication is equally critical — when leaders tell a compelling story and stay transparent about the journey, it builds trust, engagement, and alignment across the business. Ultimately, organisations that place people and culture at the centre of their digital transformation are the ones best positioned to adapt, scale, and thrive in the future of manufacturing.

Key Takeaways: Building a Digital-First Culture in Manufacturing

Culture is the foundation — Without the right mindset and behaviours, even the best technologies will fall short.

Leadership sets the tone — Executives must model digital behaviours and communicate a clear vision.

Change management is essential — Equip, support, and motivate teams through every stage of transformation.

Continuous learning drives success — Invest in digital literacy, upskilling, and cross-functional collaboration.

Communication fuels engagement — Share wins, create narrative, and build momentum across the organisation.