In today’s hyper-connected, data-driven world, digital transformation is no longer a buzzword—it’s the backbone of competitive advantage. One of the most profound shifts is happening in the world of manufacturing and supply chain optimization, where digital tools and strategies are radically changing how products are made, moved, and delivered.

From Assembly Lines to Algorithms

For much of the 20th century, manufacturing was focused inward—centred on the factory floor, driven by production efficiency, and measured by output volume. Engineers and plant managers concentrated on throughput, lean operations, and just-in-time production. But over time, a realization began to dawn: what happens outside the factory walls is just as critical as what happens within. Materials had to arrive on time, customer demand needed to be accurately forecasted, and finished goods had to be delivered efficiently and reliably. Thus, the concept of the supply chain emerged—not just as a logistical concern, but as a strategic system interconnecting everything from procurement to customer satisfaction.

Initially, supply chains were manual and siloed. Orders were placed via fax machines or phone calls. Inventory was tracked with spreadsheets or clipboards. Shipments moved with little visibility, and delays were often discovered only when it was too late to react. For those in manufacturing, this lack of end-to-end insight was frustrating. You could build a perfect product—but if raw materials were late, or a logistics bottleneck occurred, everything downstream would suffer.

This made clear a harsh truth: no matter how optimized your production line is, your output is only as reliable as your supply chain.

Enter the digital age. Technologies such as enterprise resource planning (ERP) systems, sensors, RFID tags, and later AI and machine learning began to transform how supply chains were managed. Real-time visibility replaced guesswork.

Predictive analytics began flagging issues before they became crises. Automation eliminated many of the tedious, manual tasks that once bogged down procurement and fulfilment teams. Today, digital transformation enables manufacturers and engineers to view the supply chain not as a black box, but as a transparent, dynamic, and data-rich network they can interact with in real time.

From the vantage point of someone in manufacturing or engineering, this transformation is nothing short of revolutionary. Decisions on production schedules, material substitutions, or even design changes can now ripple across the supply chain with incredible speed and precision. The factory is no longer an isolated node but an integral part of a larger, living system. And with digital solutions enabling coordination across planning, sourcing, production, and delivery, engineers and manufacturers are now co-architects of supply chain success, shaping outcomes not just in terms of efficiency, but in resilience, sustainability, and customer satisfaction.

Business Impact

Whether in manufacturing, retail, or other sectors, digital transformation has redefined supply chain management, leading to significant improvements in productivity, working capital optimization, and responsiveness to global changes such as tariffs and export controls.

Enhancing Productivity and Working Capital

Digital supply chain solutions have revolutionized traditional operations by introducing automation, real-time data analytics, and advanced forecasting. These technologies enable companies to streamline processes, reduce manual errors, and make informed decisions swiftly. For instance, integrating supply chain finance tools allows businesses to better manage their supplier base, ensuring timely payments and improved cash flow bbvacib.com.

Moreover, collaborative planning with suppliers, facilitated by digital platforms, enhances visibility into demand shifts and production schedules. This synchronization leads to smoother alignment of cash inflows and outflows, thereby optimizing working capital cycles .LinkedIn

Navigating Global Changes with Agility

The dynamic nature of global trade, marked by fluctuating tariffs and export controls, necessitates a nimble supply chain. Companies that can swiftly adapt to these changes maintain a competitive edge. For example, during recent trade tensions, some manufacturers restructured their supply chains to mitigate the impact of tariffs. A clothing manufacturer, facing high tariffs on synthetic fibre garments, redesigned its product line to incorporate a higher percentage of natural fibres, thereby reclassifying products under a lower tariff category and achieving substantial duty savings .The Supply Chain Xchange

In the pharmaceutical sector, companies like Roche and Bristol Myers have proactively shifted production to target markets and built inventories in anticipation of potential U.S. tariffs, aiming to mitigate cost increases and supply chain disruptions Reuters.

The Critical Role of Nimbleness

The ability to rapidly respond to unforeseen challenges is not just beneficial but essential. Companies that lack agility risk significant setbacks. For instance, the U.S.-China trade war disrupted global supply chains for medical devices, leading to higher costs and potential shortages. The integrated nature of the medical device industry, relying on components from over 20 countries, rendered it especially vulnerable to tariffs Financial Times.

Conversely, companies that have invested in flexible supply chain strategies are better positioned to weather such storms. By diversifying supplier bases, localizing production, and leveraging digital tools for real-time decision-making, these organizations can maintain continuity and meet customer demands despite external pressures.

Case Studies: Strategic Adaptations and Outcomes

The following table highlights how specific companies have adopted strategic supply chain adaptations to enhance resilience and performance:

| Company | Strategy Implemented | Benefits Achieved | Reference |

|---|---|---|---|

| Roche | Shifted production to target markets; built inventories | Mitigated cost increases and supply chain disruptions due to anticipated tariffs | Macemagazine |

| Clothing Manufacturer | Redesigned products to include more natural fibers | Reclassified under lower tariff category, resulting in substantial duty savings | The SCXchange |

| Medical Device Industry | Faced disruptions due to reliance on global components | Encountered higher costs and potential shortages amid trade tensions | MedTechEurope |

These examples underscore the importance of proactive and strategic supply chain management in enhancing a company’s resilience and ensuring sustained success in a volatile global market.

Core Activities & Tools

As supply chains grow increasingly complex and interconnected, it’s essential to understand the foundational activities that drive them across all industries. Whether in manufacturing, retail, healthcare, or technology, the supply chain is no longer just about moving goods from point A to point B—it’s about orchestrating a synchronized, end-to-end ecosystem that delivers value, agility, and resilience. From demand planning to last-mile delivery, every step plays a crucial role in shaping cost efficiency, customer experience, and competitive advantage.

Digital transformation has emerged as the enabler of this evolution. By embedding technologies like AI, IoT, cloud computing, and advanced analytics across each link in the supply chain, organizations are shifting from reactive workflows to proactive, data-driven strategies. This section breaks down the core functional areas of the modern supply chain and highlights the key tools and technologies being adopted to optimize operations, reduce friction, and drive smarter decision-making in real time. Whether you’re starting your digital journey or looking to refine it, understanding this landscape is the first step toward building a future-ready supply chain.

| Activity Area | Description | Digital Tools / Technologies |

|---|---|---|

| Demand Planning | Forecasting future customer demand to guide production and procurement | – Predictive Analytics – AI/ML Forecasting Tools (e.g., SAP IBP, Kinaxis) – Demand Sensing |

| Procurement & Sourcing | Sourcing raw materials or goods from suppliers | – E-Procurement Platforms (e.g., Ariba, Coupa) – Blockchain for supplier traceability |

| Inventory Management | Managing raw materials, WIP, and finished goods inventory levels | – IoT for real-time tracking – RFID & barcode systems – Cloud ERPs |

| Production & Manufacturing | Converting raw materials into finished products | – Smart Factories / IIoT – MES (Manufacturing Execution Systems) – Digital Twins |

| Logistics & Transportation | Moving goods between suppliers, factories, warehouses, and customers | – TMS (Transportation Management Systems) – Route Optimization AI – Telematics |

| Warehousing & Fulfillment | Storing and preparing goods for customer delivery | – WMS (Warehouse Management Systems) – Robotics & AMRs – Pick-to-Light Systems |

| Customer Service & Returns | Handling customer satisfaction, service, and returns | – CRM Platforms (Salesforce, Zendesk) – Reverse Logistics Tools – AI-powered chatbots |

| Sustainability & Compliance | Ensuring ethical sourcing, environmental compliance, and regulations | – ESG Reporting Software – Lifecycle Assessment Tools – Supply Chain Visibility Platforms |

Challenges in Adopting new technologies

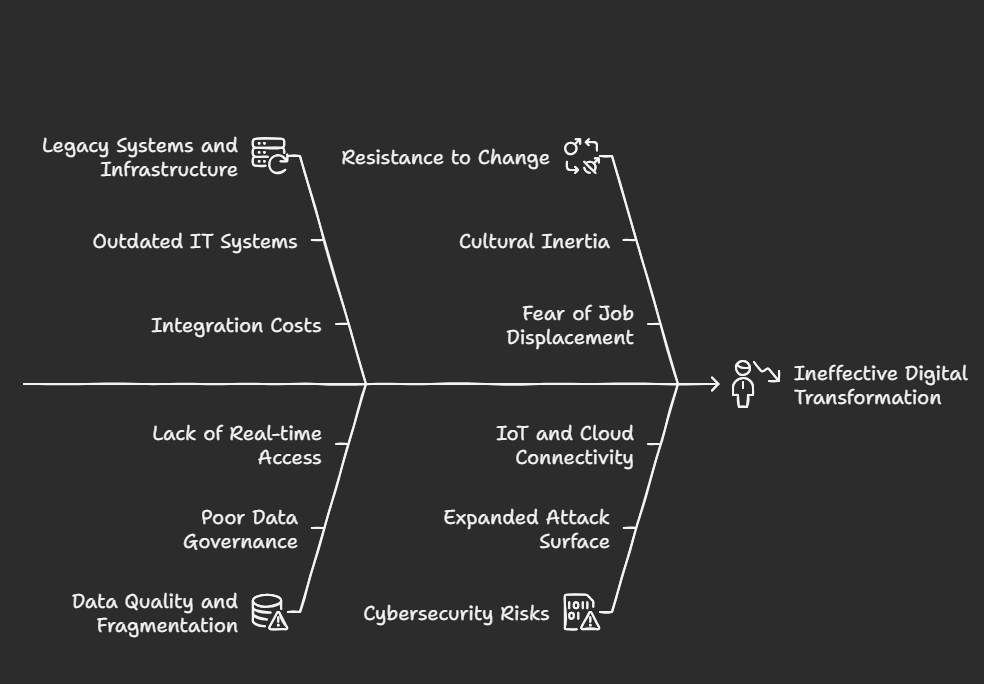

Digital transformation holds immense promise for supply chains, enabling greater visibility, efficiency, and agility—but the journey is far from simple.

Many organizations face significant hurdles that go beyond technology, including outdated legacy systems, fragmented data, skill shortages, and organizational resistance to change. These challenges can stall progress, inflate costs, or dilute impact. To successfully modernize

supply chains, businesses must navigate these complexities with strategic planning, cross-functional collaboration, and a focus on long-term value. This section explores the top challenges teams face in adopting digital supply chain technologies and why addressing them is critical for transformation success.

- Legacy Systems and Infrastructure – Most large enterprises are tied to outdated, siloed IT systems that are incompatible with newer, cloud-based or AI-driven tools. Integration becomes both technically and financially demanding.

- Data Quality and Fragmentation – Supply chains generate massive volumes of data across multiple systems and partners. Poor data governance, inconsistencies, and lack of real-time access can prevent AI and analytics tools from being effective.

- High Cost of Implementation – Digital transformation initiatives require significant upfront investments—not just in technology, but also in training, change management, and support infrastructure.

- Resistance to Change – Cultural inertia and fear of job displacement due to automation often lead to resistance from employees and middle management. This can delay or derail implementation.

- Cybersecurity Risks – As supply chains become more connected through IoT, cloud, and external vendors, the attack surface expands, making cybersecurity a pressing concern.

- Lack of Skilled Talent – There’s a growing shortage of professionals who can manage AI, machine learning, advanced analytics, and other digital tools in the context of supply chains.

- Supplier Collaboration and Transparency – Digital solutions work best when all supply chain partners participate. However, smaller or global suppliers may lack the resources or willingness to adopt digital systems, creating blind spots.

Counter Global Uncertainties

These range from geopolitical tensions and trade wars to natural disasters and pandemics—have become an ever-present challenge for businesses worldwide. These disruptions not only impact day-to-day operations but also highlight the fragility of global supply chains that are heavily reliant on distant, single-source suppliers. As a result, companies are increasingly rethinking their supply chain strategies to enhance resilience and minimize risk. Companies and countries are adoption strategies to counter these uncertainties, such as near-shoring, multi-sourcing, and in-house manufacturing. A variety of tools are being used to help the business to stay agile and responsive in an unpredictable global landscape.

| Strategy | Description | Benefits | Enabling Technologies |

|---|---|---|---|

| Near-shoring / Re-shoring | Bringing manufacturing or sourcing closer to home to reduce reliance on distant suppliers. | Reduced lead times, lower shipping costs, greater control. | Advanced Planning Systems (APS), 3D Printing, Digital Twins for plant simulation |

| Multi-Sourcing | Sourcing critical components from multiple suppliers in different locations to avoid single points of failure. | Risk diversification, better pricing leverage, improved resilience. | Supplier Portals, Blockchain for transparency, AI-based Supplier Risk Scoring |

| In-House Manufacturing | Taking control of production processes by bringing key manufacturing in-house. | More control over quality, faster innovation, and cost predictability. | Smart Factories (IoT, MES), Robotics, AI-driven Quality Control |

| Inventory Buffers / Just-in-Case | Holding higher levels of critical inventory to mitigate supply disruptions. | Avoid stockouts, improve service levels, and ensure business continuity. | AI-driven Demand Forecasting, Cloud-based Inventory Management Systems |

| Supplier Risk Management | Assessing and monitoring the geopolitical, financial, and environmental risks of suppliers. | Increased resilience, transparency, and the ability to quickly adapt to changes. | Real-time Risk Dashboards, Scenario Planning, Predictive Analytics |

Future of the supply chain

The future of the digital supply chain is set to be transformative, characterized by greater intelligence, resilience, and automation. As businesses continue to face global uncertainties and rapid technological advancements, supply chains will evolve into more agile, interconnected, and self-optimizing ecosystems. Some of these are:

- Self-Healing Supply Chains – AI-driven systems that can autonomously detect issues (e.g., weather, supplier delay) and reroute shipments or adjust orders in real-time.

- Digital Supply Chain Twins – These virtual models simulate supply chain networks under different conditions, helping leaders plan more strategically and react faster.

- AI Co-Pilots for Supply Chain Professionals – AI tools will assist human planners by suggesting decisions, flagging anomalies, and forecasting issues with context-aware insights.

- Hyper-Automation Across Functions – From procurement bots to autonomous warehouses, repetitive tasks will be increasingly handled by machines.

- Sustainability-Driven Decisions – Carbon footprint tracking and ESG analytics will be embedded into sourcing and logistics decisions, especially in response to consumer and regulatory pressure.

In Conclusion

The rapid advancement of technology and shifting geopolitical dynamics are significantly disrupting global supply chains, creating both challenges and opportunities. While digital tools like AI, blockchain, and automation have introduced complexity and new vulnerabilities—exacerbating the impact of trade wars, tariffs, and regulatory changes—they also offer powerful solutions to mitigate these risks. Technologies such as predictive analytics, real-time tracking, and digital twins enable companies to enhance forecasting, optimize operations, and improve risk management, providing the agility needed to adapt to disruptions. By strategically harnessing these innovations, businesses can not only navigate the current uncertainties but also build more resilient, adaptive supply chains for the future.

How can digital transformation improve supply chain efficiency?

Digital transformation improves supply chain efficiency by integrating technologies like AI, IoT, and blockchain, enabling real-time data analysis and automation. These tools optimize processes such as inventory management, forecasting, and decision-making, leading to reduced lead times and cost savings.

What are the main challenges companies face when adopting digital technologies in their supply chain?

Companies face challenges like integrating new technologies with legacy systems, managing fragmented data, and overcoming internal resistance to change. Additionally, high implementation costs, cybersecurity concerns, and a lack of skilled talent can delay adoption, though addressing these issues unlocks significant operational benefits.