Introduction

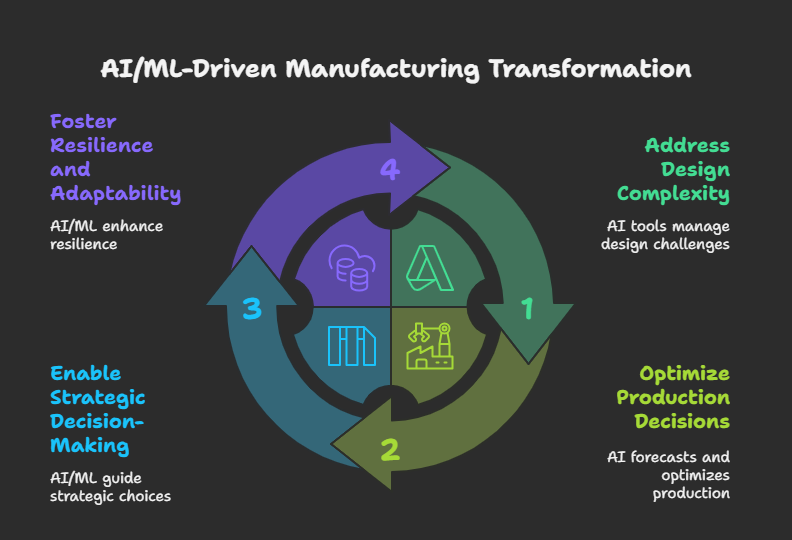

Artificial Intelligence (AI) and Machine Learning (ML) are redefining the landscape of digital transformation in manufacturing — not just by automating tasks, but by enabling smarter, faster, and more strategic decision-making across the product lifecycle. At the front end, product design faces growing complexity. Designers must ensure that products meet their functional intent, can be manufactured at scale, comply with quality standards, and align with sustainability goals. On top of this, there’s increasing pressure to select the right materials, factor in environmental impacts, and anticipate future supply chain disruptions by designing in alternatives from day one. These challenges are beyond human capacity to manage in isolation, making AI-powered design systems critical.

On the production side, manufacturers continue to grapple with foundational questions: What percentage of components should we make in-house versus buy? Should we pivot to final assembly-only business models or double down on vertical integration? How do we plan our factory networks to handle demand swings, customization, or new product introductions? Balancing serviceable products, legacy SKUs, and innovation pipelines further complicates the equation. Traditional IT systems — while necessary — are too rigid to handle these dynamic conditions. They lack the agility and intelligence required to react quickly and effectively to external disruptions or internal strategy shifts.

To tackle these interconnected challenges, AI and ML are stepping in as more than just support tools — they’re becoming strategic enablers. In design, AI-driven generative tools can create thousands of viable options based on performance, material availability, and sustainability metrics. ML models trained on historical and real-time data can recommend adjustments to improve manufacturability and reduce waste. In manufacturing, AI can forecast equipment downtime, optimize supply chain logistics, and guide workforce allocation in near real-time. These systems can simulate future scenarios and learn from outcomes, continuously improving as they go.

At the core of this transformation is a shift from reactive operations to proactive, predictive, and autonomous systems. Manufacturers who embrace AI and ML aren’t just becoming more efficient — they’re becoming more resilient and adaptive. These technologies offer the intelligence to balance complexity with speed, reduce dependency on static rules, and drive innovation through data. In the sections that follow, we’ll explore where AI and ML are already making a difference and what the next wave of intelligent manufacturing could look like.

Trends in Engineering

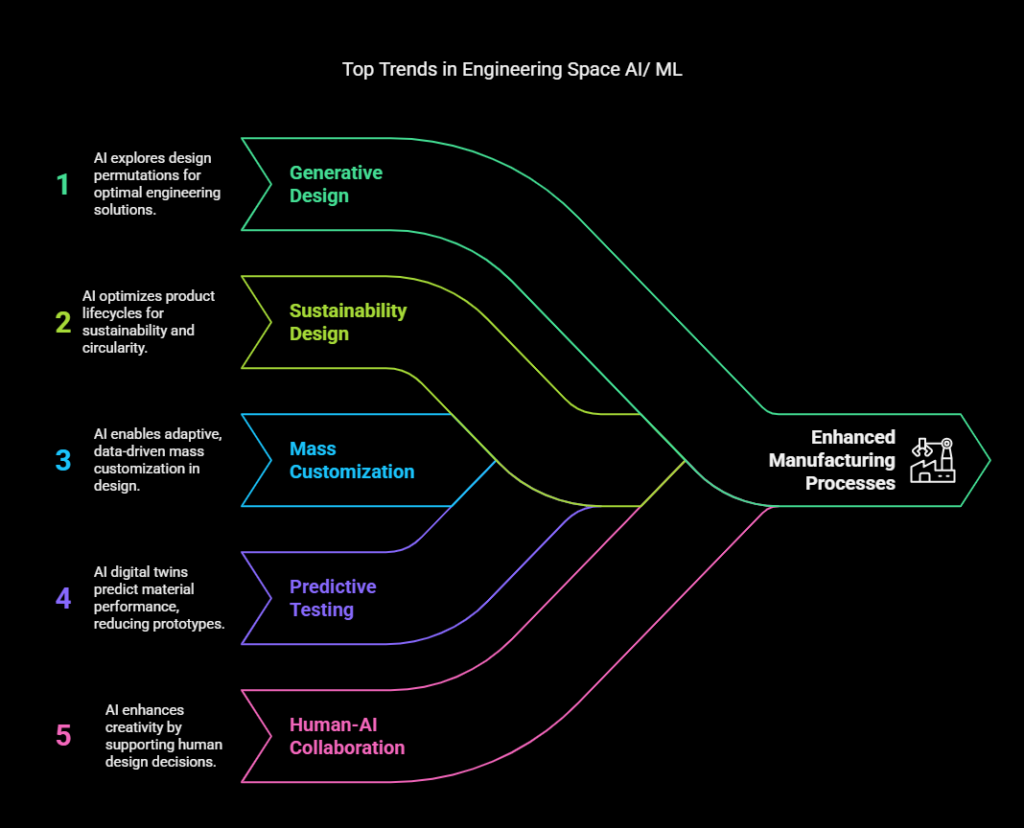

Artificial Intelligence is no longer just a back-end tool for data analysis — it’s becoming a front-line collaborator in the design process. Across industries, from aerospace to consumer electronics, AI is revolutionizing how products are conceived, developed, and refined. By integrating machine learning into design workflows, companies are not only accelerating innovation but also unlocking new levels of efficiency, personalization, and sustainability. This section explores five key ways AI is reshaping modern design — from generative engineering and sustainability-focused decision-making to predictive testing and creative collaboration. Together, these advancements mark a shift from intuition-driven to data-informed design, where human creativity and machine intelligence work in tandem to solve complex challenges.

Generative Design for Complex Engineering Problems

Generative design, powered by AI algorithms, is enabling engineers to explore thousands of design permutations based on specific parameters like weight, strength, material constraints, and cost. For instance, Rolls-Royce uses AI to simulate jet engine components under extreme operating conditions. Instead of relying solely on human intuition, their design teams use ML to uncover novel geometries that improve performance and reduce material waste — outcomes often unattainable through traditional CAD-based workflows. This shift accelerates innovation and reduces the risk of design flaws.

Designing for Sustainability and Circularity

AI is helping designers evaluate the environmental impact of their choices early in the process. Companies like Dyson are integrating machine learning tools to optimize product lifecycles — from materials to recyclability. For example, Dyson’s vacuum designs increasingly use lightweight, modular parts, informed by data-driven simulations that measure durability versus carbon footprint. AI tools provide real-time trade-offs, allowing designers to make greener choices without compromising performance or cost.

Mass Customization Through Data-Driven Design

Traditional design worked towards mass production; AI is now enabling mass customization. Ford is using machine learning to design vehicle components and interfaces based on consumer preferences and usage patterns gathered through connected vehicle data. Whether it’s designing seat ergonomics or infotainment systems, AI allows for faster iteration based on real-time customer feedback, making the design process far more adaptive and user-centric.

Predictive Testing and Digital Twins

Gone are the days of building multiple physical prototypes. JCB, known for its construction equipment, now uses AI-powered digital twins to test durability, stress, and wear under different working conditions. Machine learning models can predict how materials will perform over time or under unusual stresses, reducing both design lead time and physical resource use. This means traditional validation stages are being reshaped — with AI simulating months of testing in days.

Human-AI Collaboration in Creative Decision-Making

Rather than replacing designers, AI is increasingly a co-pilot in the creative process. At companies like Rolls-Royce and Ford, AI helps designers spot anomalies, suggest improvements, or generate variations based on previous project data. However, the final aesthetic and functional decisions still lie with human teams, who now focus more on ideation, storytelling, and brand alignment while offloading repetitive and analytical tasks to AI. This human-in-the-loop approach preserves creative integrity while boosting efficiency and innovation.

Refences for Engineering

| Company | Example/ Use Case | Reference Link |

| Dyson | Advanced robotics and AI for autonomous machines and product design | Dyson Robotics Research |

| Rolls-Royce | Intelligent Engine initiative using AI/ML to design predictive, adaptive jet engines | Rolls-Royce Intelligent Engine |

| JCB | AI in telematics and predictive maintenance influencing future product design | JCB LiveLink Telematics |

| Ford | AI and generative design for light weighting and next-gen vehicle platforms | Ford Generative Design |

Trends in Manufacturing

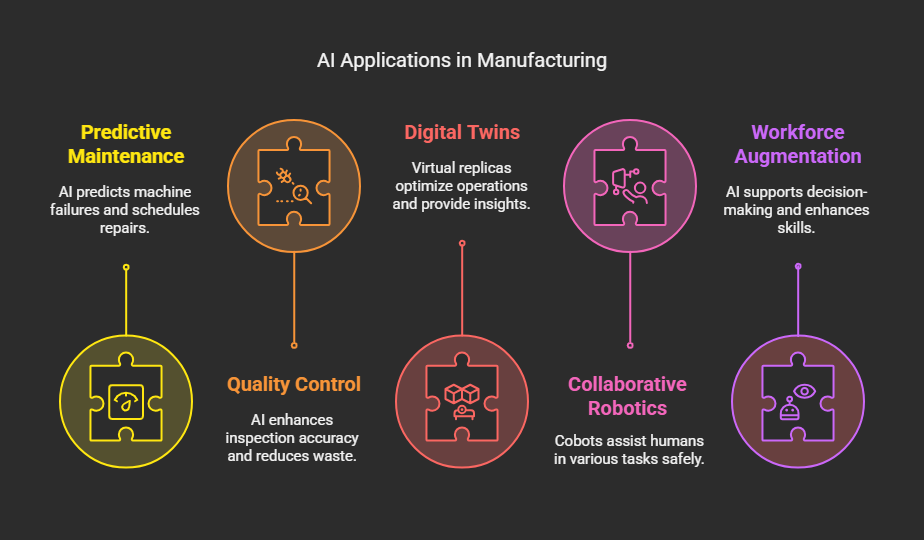

As product design evolves through AI and ML augmentation, the ripple effects are equally transformative on the shop floors and factories that bring these designs to life. The “factory of the future” is no longer a distant vision — it’s emerging today through the convergence of intelligent automation, data-driven operations, and human-machine collaboration. Manufacturers across industries like aerospace, automotive, heavy engineering, and oil & gas are rethinking how production environments operate — not just for efficiency but for resilience, adaptability, and smarter decision-making. These new paradigms are reshaping roles, workflows, and capabilities across the manufacturing value chain.

Predictive Maintenance and Self-Healing Machines

AI is enabling machines to predict potential failures before they occur. Using historical data, vibration analysis, temperature readings, and other sensor inputs, predictive maintenance algorithms can schedule repairs or even initiate self-corrective measures, reducing downtime and extending asset life.

Example – Rolls-Royce (Aerospace): Through its Engine Health Management system, Rolls-Royce uses AI to monitor engine performance in real-time, predicting when maintenance is required long before a failure occurs — ensuring aircraft stay airborne and operational longer.

AI-Powered Quality Control and Inspection

Machine learning models trained on defect patterns are now outperforming traditional visual inspections. AI-enabled vision systems can detect micro-level defects on assembly lines, improving precision and reducing waste. These systems continuously learn from each inspection to enhance detection accuracy.

Example – BMW (Automotive): BMW uses AI-based image recognition to inspect vehicle components for imperfections in real time, reducing inspection time and human error while boosting production efficiency.

Digital Twins and Real-Time Simulation

Digital twins — virtual replicas of physical assets — powered by AI and IoT, allow manufacturers to simulate and optimize operations in real time. These twins provide insights into process inefficiencies, energy usage, and supply chain disruptions.

Example – Shell (Oil & Gas): Shell employs AI-driven digital twins of its offshore platforms to run simulations, predict safety risks, and optimize energy usage, helping improve operational decision-making while ensuring employee safety.

Collaborative Robotics (Cobots)

Unlike traditional robots, cobots are designed to work side-by-side with humans, guided by AI to adapt to changing environments and tasks. Cobots can augment the workforce, handling repetitive or hazardous tasks while freeing up humans for more strategic roles.

Example – Ford (Automotive): Ford has deployed AI-enhanced cobots on its assembly lines to assist human workers in tasks like lifting and welding. These robots adjust in real time to human motion, creating a safer and more productive workspace.

Workforce Augmentation and Intelligent Decision Support

AI is becoming a “co-pilot” for factory workers and managers, providing real-time decision support, operational insights, and skill augmentation. From smart glasses to AI-driven ERP dashboards, workers are empowered with contextual, data-driven guidance.

Example – GE Vernova (Heavy Engineering): GE uses AI-enabled platforms to give field engineers intelligent recommendations during turbine servicing, boosting accuracy, reducing repair times, and enhancing worker confidence on-site.

References for Manufacturing

| Category | Example | Technology Used | Reference Link |

| Predictive Maintenance and Self-Healing Machines | Rolls-Royce uses AI to monitor and predict aircraft engine maintenance. | Engine Health Management, AI, IoT | Rolls-Royce: IntelligentEngine |

| AI-Powered Quality Control and Inspection | BMW uses AI for real-time defect detection in vehicle components. | AI-based Image Recognition, Machine Vision | BMW: Quality Control Through AI |

| Digital Twins and Real-Time Simulation | Shell applies AI digital twins for offshore platform simulations. | AI Digital Twins, Real-Time Analytics | Shell + Microsoft AI Digital Twins |

| Collaborative Robotics (Cobots) | Ford uses AI-powered cobots to assist workers in assembly tasks. | AI-enhanced Cobots, Real-Time Motion Sensing | Ford: Man and Machine Work Hand-in-Hand |

| Workforce Augmentation and Intelligent Decision Support | GE Vernova uses AI to guide engineers during turbine maintenance. | AI Decision Support, Predictive Analytics | GE Vernova: AI for Energy Transition |

Conclusion: AI-Driven Innovation

As AI and machine learning continue to evolve at breakneck speed, their impact across engineering and manufacturing is becoming impossible to ignore. From generative design to predictive testing, these technologies are reshaping how products are imagined, built, and improved. However, for businesses to fully harness these emerging trends, getting the fundamentals right is critical. Agility, high-quality data, and a modern, flexible technology stack are not just enablers — they are prerequisites.

Organizations that lack these foundations risk stumbling in their AI journey. On the flip side, some companies are choosing to leapfrog — adopting AI/ML as a core operating model from the outset and retrofitting the necessary structures around it. While bold, this “AI-by-default” approach can accelerate transformation if backed by strong leadership and a culture of continuous learning. Ultimately, whether through steady groundwork or strategic leaps, success in the age of intelligent design depends on aligning technology, talent, and vision.

Example: AI-By-Default

An illustrative example of a company embracing an “AI-by-default” approach is Shopify. In April 2025, Shopify’s CEO, Tobi Lütke, mandated that before any new hires are approved, managers must demonstrate that artificial intelligence cannot perform the tasks in question. This policy underscores Shopify’s commitment to integrating AI across its operations, positioning AI utilization as a fundamental skill for all employees. Performance evaluations now include assessments of AI usage, reflecting the company’s strategy to enhance efficiency and innovation through AI adoption.

How is AI transforming engineering and manufacturing?

AI is revolutionizing engineering and manufacturing by enabling generative design, predictive testing, and real-time data-driven decision-making. Companies use AI to optimize product performance, reduce material waste, accelerate prototyping, and create more personalized and sustainable products.

What should businesses do before adopting AI and machine learning?

Before implementing AI and machine learning, businesses should focus on building strong foundations — including data quality, agile processes, and a scalable technology stack. Without these basics, AI efforts may face integration issues or fail to deliver real impact.